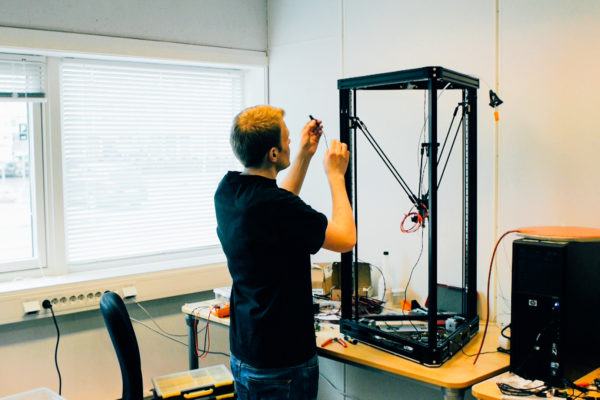

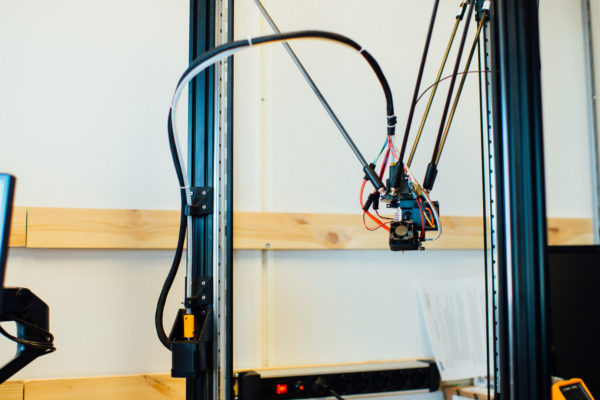

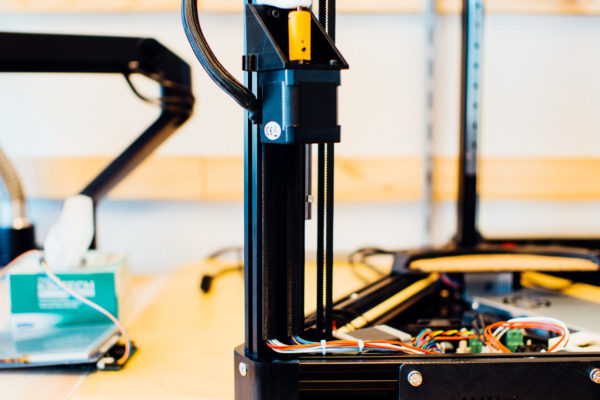

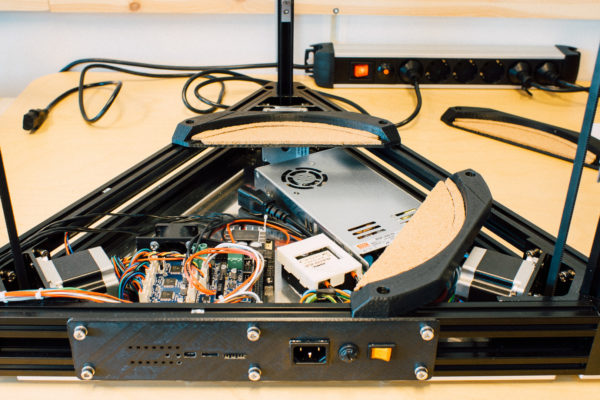

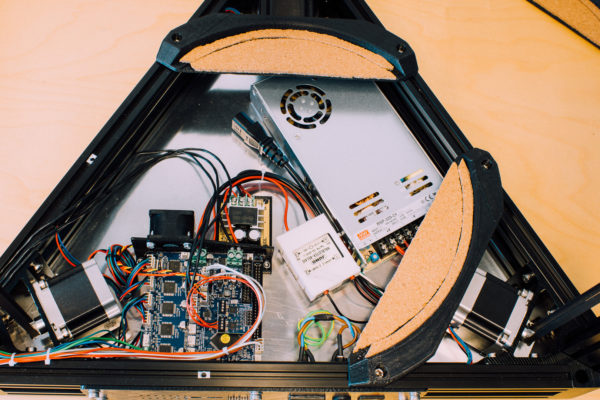

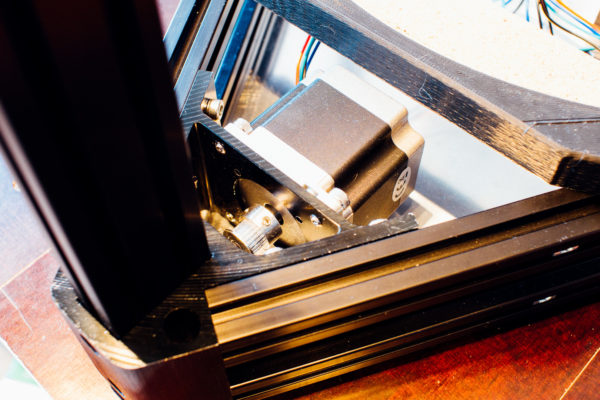

Late 2016 we started designing and building a new 3D printer for internal use. We wanted to maximize both speed, accuracy and build-size, so we ended up with a large Kossel-based delta printer design.

We have written several blog posts about this project, where we go into further detail around the different aspects of the printer:

- Part 1: Parts and planning

- Part 2: Building update

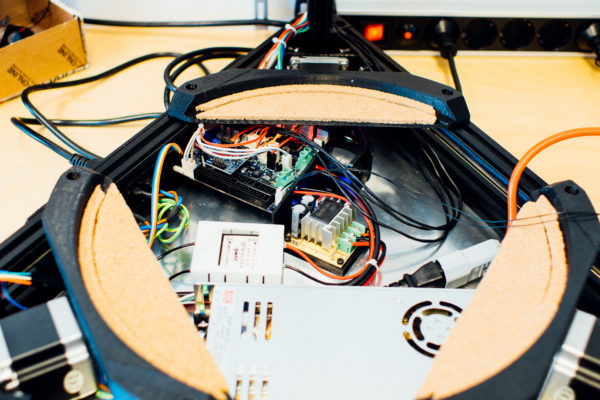

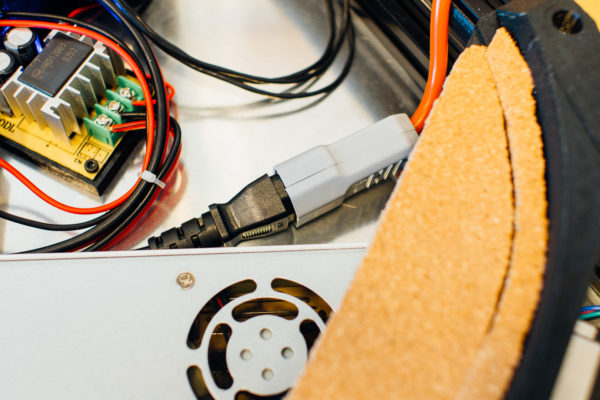

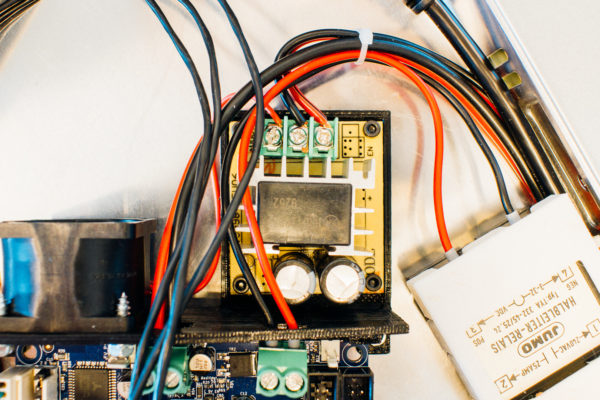

- Part 3: Electronics and wiring

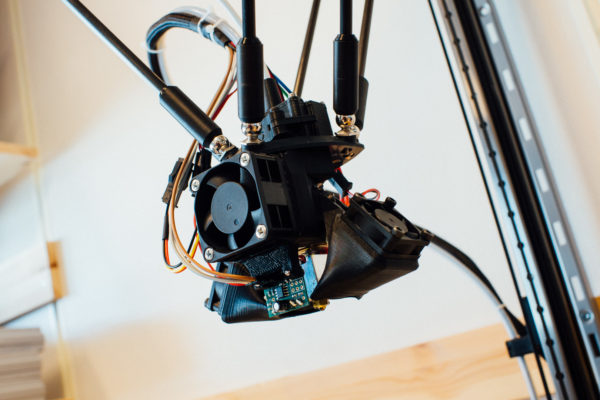

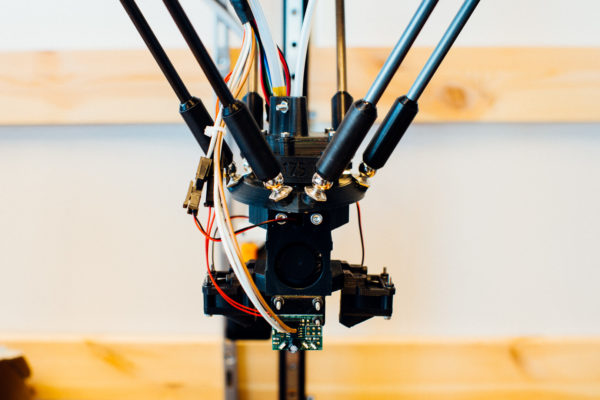

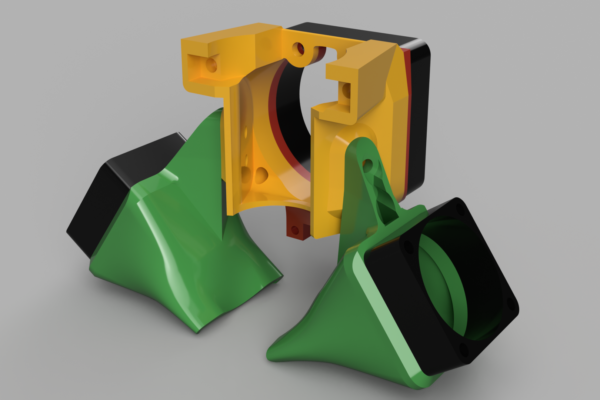

- Part 4: Modifying the effector

- Part 5: A video from the Building

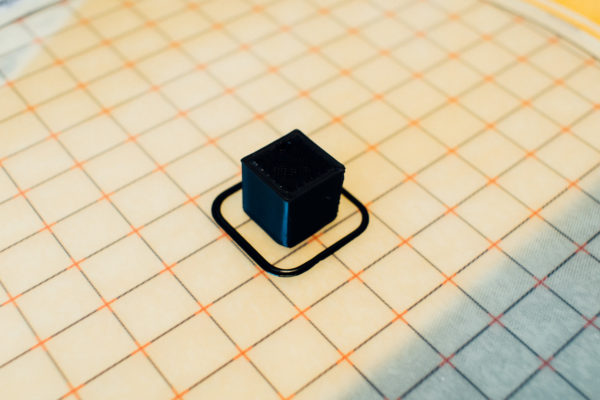

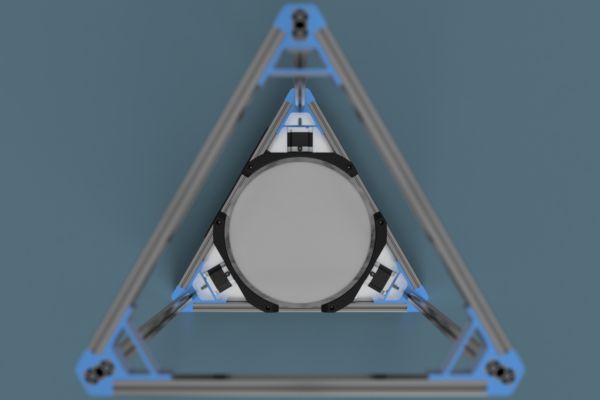

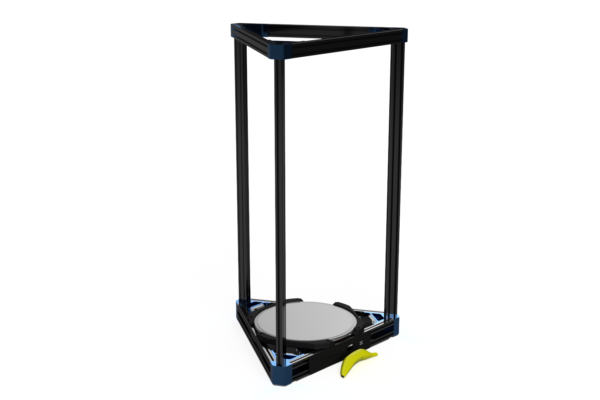

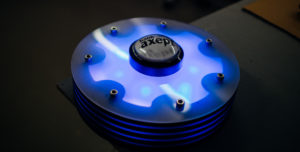

The light head with Flex3Drive effector (flexible shaft extrusion) and E3D Volcano hotend gives it speed. High quality parts and custom cooling give it accuracy. The 310 mm diameter build plate and the 1 meter tall frame gives us what we need in terms of print size. The printer also features PrintBite bed adhesion, WiFi and web-interface, touch screen and filament-out sensor, among other things.

The printer is still continuously in development, however fully operational.