When printing with a FDM printer, such as our Solidoodle, the surface becomes kind of “liny”. We use this priniting technology to create different system parts, where surface appearance is not of importance. But what to do if you want a smooth part?

ABS can be treated with Acetone. The Acetone chemically melts the plastic, so yes, details will/can be lost. A common method is to give the part a Acetone vapor bath treatment, which will result in a (hopefully) supersmooth part, looking a lot like an injection molded one.

But there exist at least one other method to smooth out the surface: Sanding.

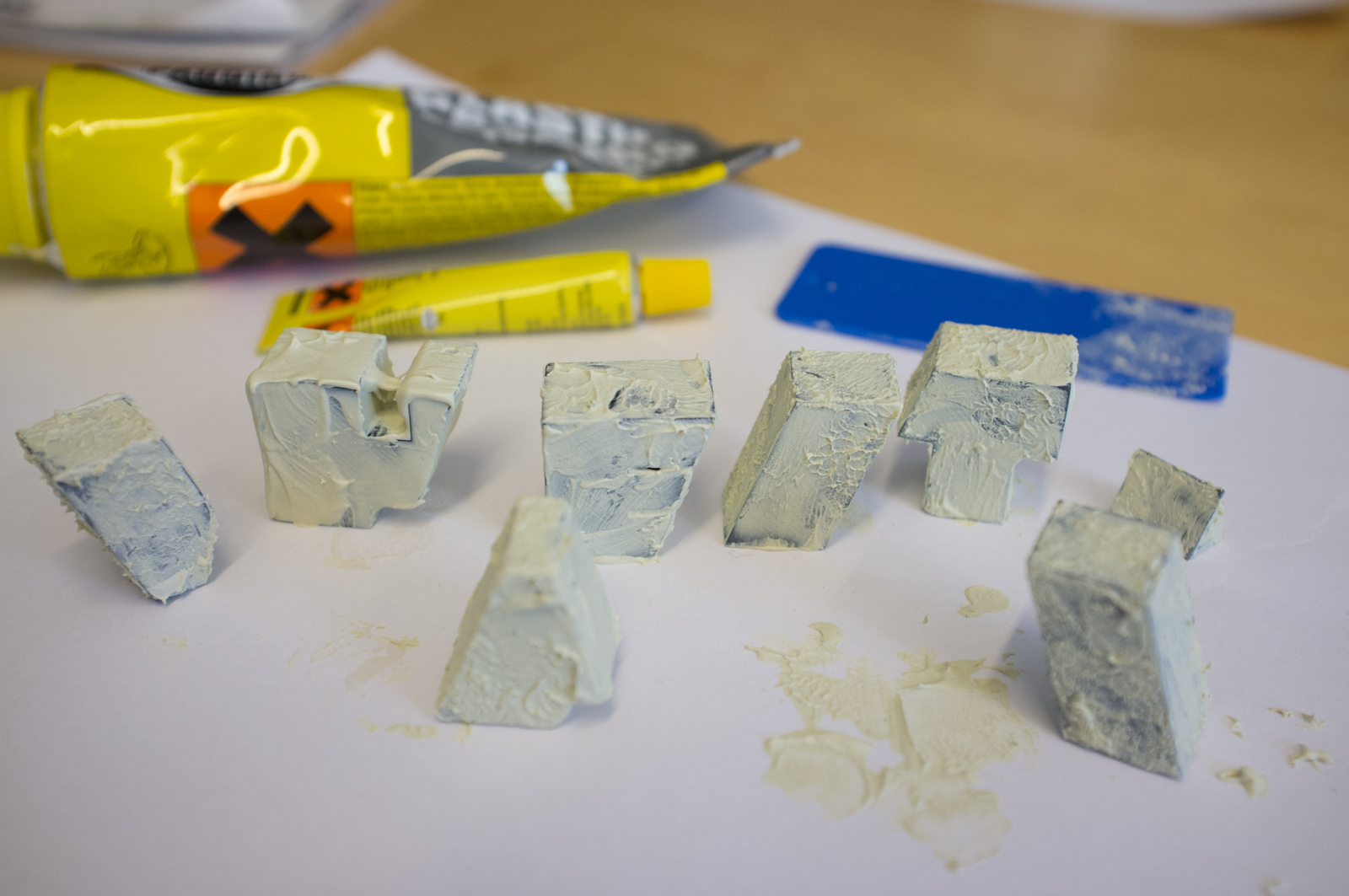

If you sand and plaster the part, you also need to coat it to hide the filler. Compared to the Acetone process this concists of at least three steps:

- Applying filler

- Sanding

- Painting

And sanding can be really difficult on complex surfaces!

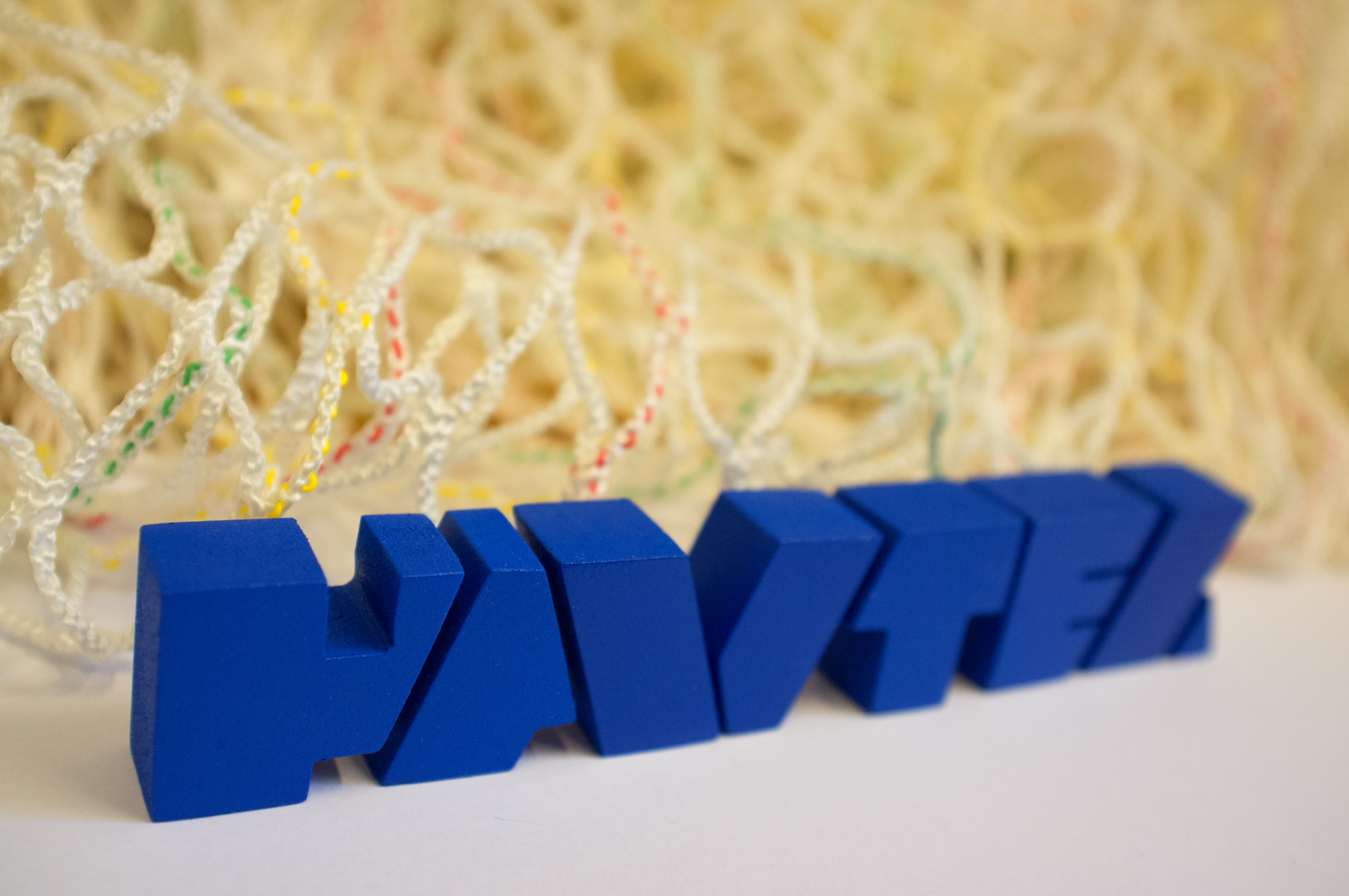

I’m finishing something that is pretty simple to sand: the Havtek logo.

Yes, I printed the logo on a pretty uncalibrated machine. But since this part was going to be sanded, that didn’t matter..

Spray-filler will be used next time. Less messy..

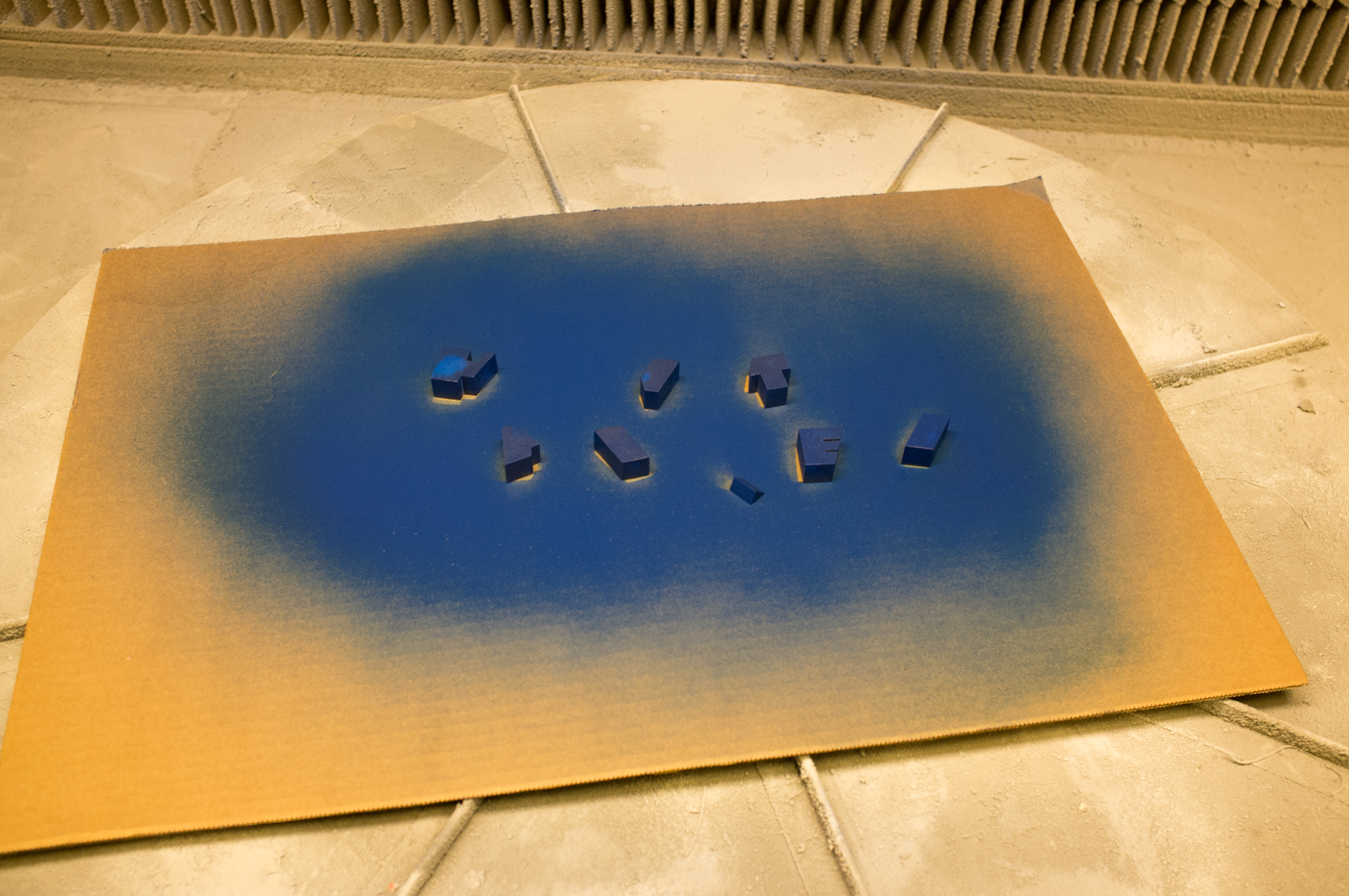

The trick with applying spray paint is to be patient. Apply many thin layers. I was kind of impatient, resulting in some roughness in the paint, which I had to sand down before applying more paint =/

The paint cloud coming out of the spray I used consisted of fairly large drops, resulting in a kind of rough surface. But that’s cool:)